The digitalization and connectivity of systems, processes and machines is now already a deciding factor in the struggle to gain a competitive edge. However, Industry 4.0 is still not on the top of the agenda for all companies. That could be because implementing Industry 4.0 projects comes with its own challenges, as the results of this study show.

The IDG study “Industry 4.0 2017”

A long overdue paradigm shift in industrial production

While some experts are already speculating about what will come after Industry 4.0, many companies in Germany are still putting off the latest industrial revolution. Indeed, 90 percent of all companies surveyed believe that Industry 4.0 will be a relevant topic for the years to come, but there is still a lot of catching up to do when it comes to implementation, particularly for SMEs.

Industry 4.0 makes it possible to avert machine downtime before it happens, avoid empty runs in logistics and use resources efficiently in production. The range of possible applications is broad, and the potential is enormous, as confirmed by the high success rate of Industry 4.0 projects that have already been implemented. The outlook is clear: No sector will remain untouched by this paradigm shift. Today’s industrial revolution is just as unstoppable as the industrial revolutions of the past.

The study contains

- key findings and detailed figures on how decision makers and IT specialists from 339 companies assess Industry 4.0, as well as a look at the future of IoT,

- answers to the questions of where the most action is needed in German companies and what benefits Industry 4.0 projects can confer,

- an estimate of how satisfied companies are with their Industry 4.0 projects to date,

- an overview of the technological risks to be expected in the implementation of Industry 4.0 projects, and

- an evaluation of what the crucial unmissable Industry 4.0 technologies are.

Find out how high-ranking decision makers assess the current state of Industry 4.0 for their companies (only available in German).

The study was carried out by IDG Research Services in February 2017. The survey included 339 companies of various sizes and with varying levels of annual income from a range of sectors. Lufthansa Industry Solutions is a partner of the study.

All key findings and additional study results can be found in their entirety in the study itself, which you can download for free (only available in German). Below are some of the study’s most important insights.

In many areas, Industry 4.0 has yet to come into play

Thirty-six percent of companies rated the relevance of Industry 4.0 as high or very high at the time of the study. That is a comparatively small value when you consider the 34 percent who rate it as low or very low. It is a different story when looking to the future: 65 percent expect Industry 4.0 to be highly or even very highly relevant to them over the next two to three years.

Only a few companies have implemented relevant projects so far

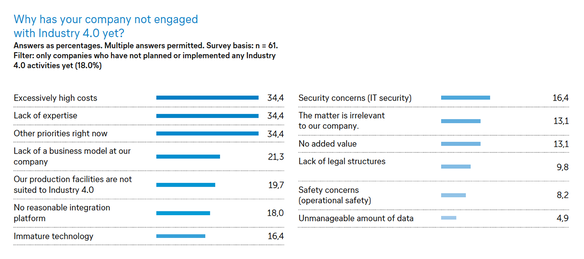

Only 4 percent of companies are already implementing Industry 4.0 projects over a longer time horizon, while 15 percent have already completed individual projects, giving them their first experiences with the approach. On the other hand, 18 percent are not planning to implement any such projects. Why? Most companies believe that the biggest obstacle is excessively high costs and a lack of expertise, or they simply have other priorities.

The success rate proves forward-looking companies right

The following figures show that Industry 4.0 projects bring real added value: 21 percent of those surveyed are very satisfied with the results, and 45 percent are satisfied. At 67 percent of the companies, the benefits were clear in less than 3 months. The survey did not find any evidence of failed projects. That should give those who are still hesitating pause for thought.

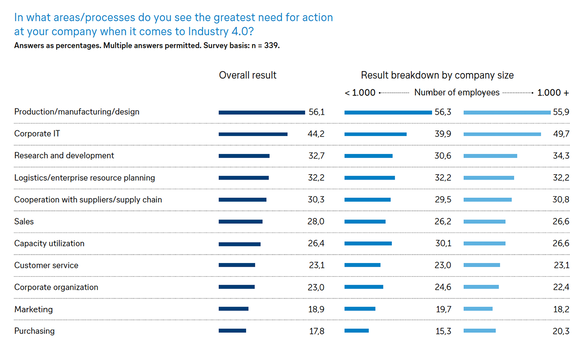

Catch-up needed in production

In many areas, there is a lot of catching up to do to prepare for Industry 4.0. The most frequent areas mentioned in this respect were production (56 percent) and IT (44 percent). The companies say that they also need to raise their game in research and development as well.

Visible benefits in terms of costs and competitive advantage

Where are the specific benefits of Industry 4.0 that justify the expense and investment? Forty-five percent of companies believe that an orientation toward Industry 4.0 would give them an advantage over the competition. Forty-one percent are saving on production costs, and 40 percent are saving costs overall. Most respondents said that the desired benefits from implementing Industry 4.0 projects are to be found in current projects. Hardly any of them aim to develop new business models, although the potential is there.

Potential risks of Industry 4.0

In spite of all the positive forecasts, companies are still hesitating to fully engage with Industry 4.0. What are the factors stopping them? The major fear is the concern about a possible hacker attack, which 48 percent regard as a threat. This is followed by the fear of industrial espionage and loss of production, which 30 percent of respondents admitted to.

To see all the results in detail, click here to download a free PDF of the “Industry 4.0 2017” study (only available in German).